Brief introduction of fixed bed catalyst

I. introduction of the project

The fixed bed catalyst production project covers an area of about 5,000 ㎡, with a building area of 2,000 ㎡, complete public utilities, and more than 40 sets of catalyst production equipment. It has a complete fixed bed catalyst production system, and the available production units mainly include: pretreatment of raw catalyst powder, impregnation, molding, drying/roasting, screening and environmental protection treatment, etc., which can meet the production of various fixed bed catalysts.

II. Equipment introduction:

1、stirred-tank reactor(2 sets)

Type: 5000L, with jacket, which can be filled with steam or circulating water

2、impregnation kettle(2 sets)

Type: 5000L

Production capacity: 3.0T/ batch in total

3、 continuous coating machine(2 sets)

Type:BY-1000

Performance parameters: Material 304 pot is lined with tetrafluoroethylene

The pan body diameter is 1000mm

Production capacity: 20-40kg/ set * times

4、kneading machine(2 sets)

Type: HNJ-1000L

Performance parameters: the hopper volume is 1000L

Rotational speed 23 r/min

Production capacity: 300-350kg/ set * times

5、extruding machine(2 sets)

Type: DJ-100

Performance: extrusion specification ≥φ1.2㎜

Standing sieve plate 4.0mm

Production capacity: 240-300kg/h* sets

6、rolling machine(2 sets)

Type: NYJ-350

Performance parameters: 0.3-5mm thick pressed sheet

Capacity and pressure ≤15T

Production capacity: 1000kg/h* sets

7、granulator(3 sets)

Type: ZLJ-160

Performance parameter: material 304

Production capacity: 150kg/h* sets

8、V-Mixer (1 set)

Type: 1000L

Performance: Material of contact material of cylinder is 304

With automatic liquid spraying device and timing

Production capacity: 600L/ batch

9、tablet press(7 sets)

Type: GYJ25-5A

Performance parameters: capacity ≤ 300,000 pieces/hour

Product specifications φ5*5㎜

Production capacity: 150kg/h, about 20-25kg/h per unit

10、meshbeltfurnace(1 set)

Type: 35000×2300×2000

Performance parameters: the heat source is natural gas and the design temperature is 550-650 degrees

The net width is 1.2m

Production capacity: 3-6T/ day

11、roller kiln(1 set)

Type: 20000*1110*350mm

Rated temperature ≤950℃

Electric heating power 300kw

Production capacity: 2-3T/ day

12、hot air circulating oven(1 set)

Type: CT-C-IV

Performance: Material 304, electric heating power 60KW

With dehumidifying fan, drying temperature ≦140℃

Production capacity: 400kg/ batch

13、circular vibrating screen (1 set)

Type: φ1200

Performance parameter: material 304

Production capacity: 1000kg/h

14、linear Vibrating screen (1 set)

Type: 1000*2000

Performance parameters: Material 304, with two vibrating motors

Production capacity: 2000kg/h

15、steam drying oven(4 sets)

Drying room specification: 7000*3000*4000, drying temperature 80 ~ 110 degrees

Each drying room has 5 mobile drying cars and 300 pallets, and the drying capacity of each drying room is about 3 tons/batch

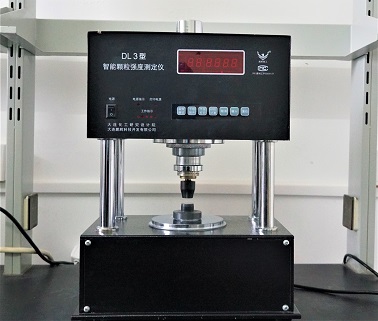

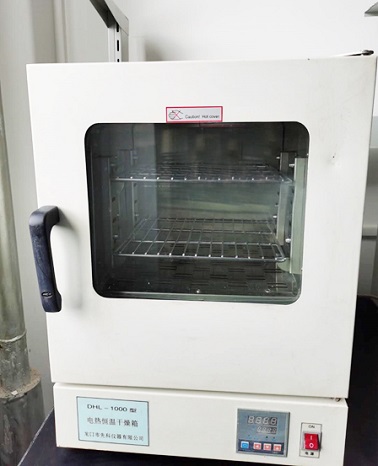

III. Testing Equipment

1、drying oven(1 set)

2、muffle furnace(1 set)

3、strength tester(1 set)